We offer a complete service from surveying to consulting. We are able to capture data on any shape and material and rework it by generating 3D solid models in order to achieve the desired purpose; whether it is related to new product functionality or the simplification of a design for feasibility issues, or more simply to provide CAD models replicating a specific product.

The functionalities are indeed multiple:

- Digitising a physical model and reworking the generated CAD model

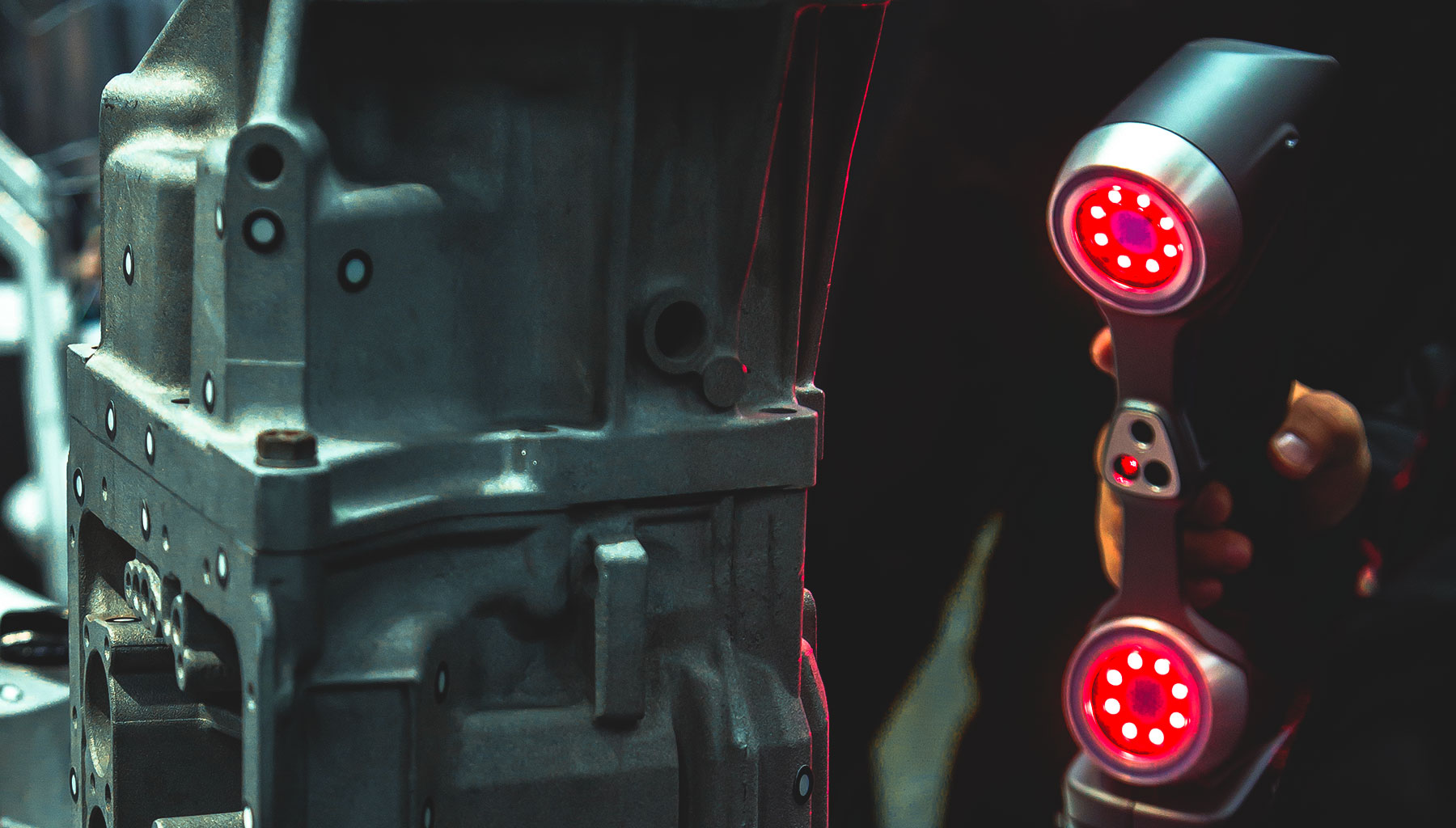

- Dimensional checks with laser scanning, comparison of physical model with CAD model

- Contact dimensional checks